electrification has always been a sign of the progress and development of human society. with the strong development momentum of china's economy. all kinds of electrical equipment are increasingly entering into various fields of the national economy and people's life, and at the same time, the fire caused by electrical reasons is also on the rise. according to the statistics of the fire department, the number of fires caused by electrical reasons in the city ranks first among all kinds of fire accidents.

the maintenance and management of power system and electrical equipment has been an unavoidable topic in power operation for a long time. its quality is high or not, whether it is polluted, whether it is due to the existence of harmonics and other impurities, resulting in a large amount of power consumption, which brings unnecessary losses to the enterprise; capacity operation will cause certain damage to the insulation of equipment cables. other types of accidents include: high-voltage fault analysis of substations, unexplained power loss of low-voltage loads at all levels, multiple unreasonable damages to electrical components, etc. this may result in electric shock, injury, destruction, and electrical fire.

electricity safety includes both the stability of power supply and normative electricity consumption, providing the necessary electric energy resources for the development of various industries, ensuring the stable development of various industries, strengthening the public's awareness of electricity safety, and strengthening the safety protection of electricity consumption. to ensure the safety of people's lives. electric energy itself is relatively unique. the stability of power supply and the safe use of electricity by users belong to the basic content of electricity safety management. strengthening the inspection of electricity consumption is an effective guarantee for the safety of electricity consumption, minimizing the safety accidents that may occur during the transmission and use of electric energy, reducing property losses of the masses, and avoiding casualties and soon.

noa|noa provides supplier technical assessment services, including but not limited to:

1. electrical design review

the design document is not only the foundation of a project, but also the guiding ideology and working principle throughout the whole process of the project. at different stages of the design, reviews will be done with different priorities:

1. conceptual design stage (schematic design stage): assist in completing the demonstration of the scheme, especially for the power transmission scheme, substation location selection, power supply and distribution principles, etc.;

2. preliminary design stage: review the completeness and accuracy of main equipment and material selection, and theoretically analyze and judge the rationality of the investment budget; complete the review and verification of basic calculation work;

3. construction drawing design stage: on the premise of meeting the investment budget, analyze and interpret the design drawings in detail, in order to find out the design omissions and hidden problems, and put forward reasonable solutions;

4. as-built drawing stage: after on-site investigation, the as-built drawings are verified or completed according to the actual situation on site.

2. electrical safety inspection and evaluation

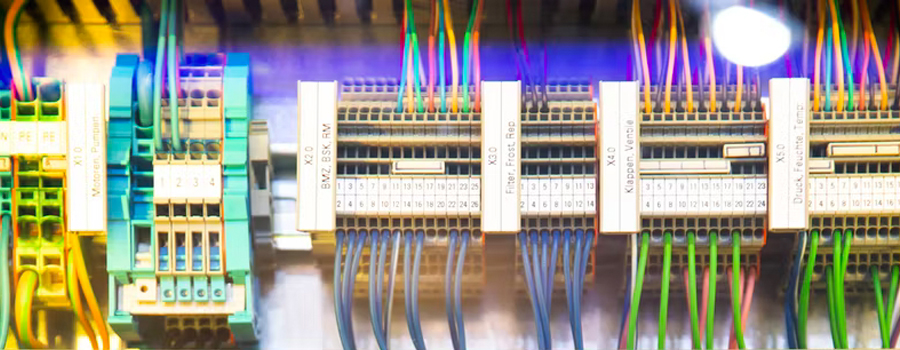

electrical inspection includes a series of tests done in the electrical system, from the power supply line to the terminal equipment, including high and low voltage equipment. use the most advanced testing equipment including ultrasonic detector, grounding resistance tester, infrared thermal imager, infrared thermometer, harmonic tester, ground resistance tester and other working conditions of electrical components, system grounding resistance and electrical equipment contacts check for fever. infrared thermal imaging inspection can avoid electrical fires caused by overheating of electrical junctions.

the specific electrical system inspection contents are: grounding zero connection, cable insulation, switch control cabinet (including switches, sockets, lighting, etc.), motors, generators, batteries (groups), and cable trays; through on-site inspection and analysis, the root cause of the accident was found. , to provide customers with similar hidden dangers that may exist, specific inspection and evaluation, according to the power supply and distribution system and electrical equipment at all levels. and divided into the following ways:

1. review the use, repair, maintenance plans and records of electrical equipment;

2. collect and analyze operating parameters and evaluate safe operating status;

3. possible problems found during testing and inspection of electrical equipment;

4. make a reasonable analysis and judgment on the working capacity and service life of the existing equipment;

5. propose targeted rectification plans and formulate corresponding repair and maintenance plans for electrical equipment.

what is the process of electrical safety inspection?

(1) clearly check the object;

(2) delineate inspection items;

(3) clear inspection methods, procedures and tools;

(4) clarify the standardized technical requirements of the inspected object. the comparison and judgment method of the inspection results;

(5) check the inspection objects item by item and give the inspection results;

(6) issue an inspection report.

what are the types of electrical safety hazards?

electrical safety hazards include operation hazards, installation hazards, management hazards, "two votes and three systems" hazards, electric shock and electromechanical injury hazards, etc.

what are the objects of electrical safety inspection?

(1) check whether the insulation of electrical equipment is damaged;

(2) whether the insulation resistance is qualified;

(3) whether the exposed live parts of the equipment are protected;

(4) whether the shielding device meets the requirements and whether the safety distance is sufficient;

(5) whether the protective zero connection or protective grounding measures are correct, and whether the reliable protection device meets the requirements;

(6) whether the lanterns and local lighting voltages are safe voltages or whether safety measures have been taken;

(7) whether safety appliances and electrical fire extinguishing equipment are complete;

(8) whether the installation of electrical equipment is qualified, and whether the installation location is reasonable;

(9) whether the electrical connection parts are in good condition;

(10) whether the electrical equipment or electrical circuit is overheated.

what are the safety measures for using electricity?

(1) when the electrical equipment fails, the power switch should be turned off first, and then the electrician should repair it. repairs by non-electricians are strictly prohibited to avoid accidents.

(2) all electrical equipment such as distribution boxes, switch boxes, electrical cabinets, distribution boards, motors, etc., should be kept clean and dry. do not stack debris around or inside. it is not allowed to rinse with water, let alone scrub with alkaline water, so as not to damage the insulation. when wiping the equipment, the power will be cut off and stopped.

(3) electrical equipment shall not operate with illness or failure. when the electrical equipment operates abnormally and may endanger personal safety, the operation of the equipment should be stopped according to the procedures specified in the operating regulations.

(4) before any electrical equipment is confirmed to have no electricity, it is always considered to be powered, do not touch it blindly, and non-relevant personnel are not allowed to move the signs such as "no closing", "someone working" on the electrical equipment and temporary installations. safety fence.

(5) electrical equipment (including power tools) must have protective grounding or zero-connection measures, and should be checked frequently to ensure that the connection is firm and reliable.

(6) when operating the switch, be sure to close the switch cover to prevent arcing and splashing of molten metal from hurting people. do not touch switches, sockets and lamp caps with wet hands.

(7) the insulation of electrical equipment and lines must be good. switchboards, knife switches, push-button switches, and latches that workers often touch and use must be kept safe and intact, and must not be damaged.

(8) when it is necessary to move the fixedly installed electrical equipment such as lighting lamps, electric welding machines, submersible pumps, etc., the power must be cut off before moving. when the wire is caught by an object or the length of the wire is not enough, do not pull hard to avoid damage.

tel: 86-400 821 5138

fax: 86-21 3327 5843

email:noa@noagroup.com