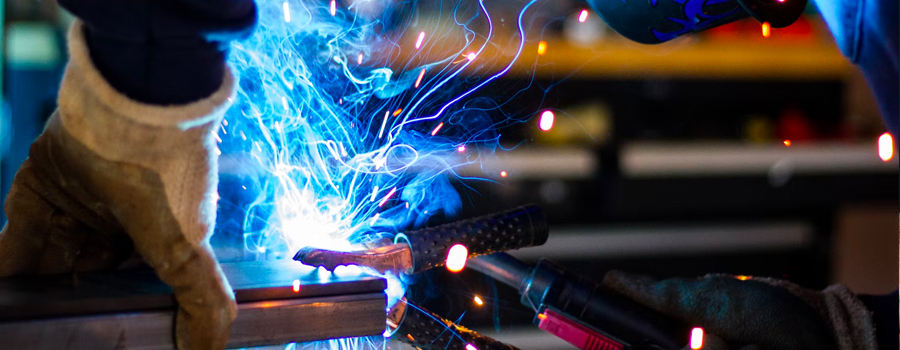

welding techniques are primarily applied to metal substrates, with commonly used methods including arc welding, tig welding, co2 shielded welding, oxyacetylene welding, laser welding, and electric resistance welding. non-metallic materials like plastics can also be welded. there are over 40 metal welding methods, primarily categorized into three major types: fusion welding, pressure welding, and brazing.

fusion welding involves heating the interface of the workpieces to a molten state during the welding process, completing the joint without applying pressure. in fusion welding, the heat source rapidly melts the interface of the two workpieces, forming a molten pool. as the heat source moves forward, the molten pool cools and forms a continuous weld seam, connecting the two workpieces into one.

welding is a localized rapid heating and cooling process. the welded area, constrained by the surrounding material, cannot freely expand or contract, resulting in welding stresses and deformation upon cooling. it's essential to eliminate welding stresses and correct welding deformations for critical products post-welding.

modern welding technology can produce weld seams without internal or external defects, with mechanical properties equal to or even surpassing those of the base materials being joined. the spatial arrangement of the materials being welded is referred to as the welding joint. the strength at the joint is not only affected by the quality of the weld seam but also by its geometric shape, size, stress conditions, and working conditions. basic joint forms include butt joints, lap joints, t-joints, and corner joints.

welding processes play a crucial role in manufacturing costs and product quality. to prevent serious issues during production and service, comprehensive quality control must begin from the product's design stage, encompassing material selection, manufacturing, subsequent inspections, and especially focusing on welding quality systems, welding processes, and the qualifications of welding personnel.

noa provides welding training and certification services, including but not limited to:

1. factory certification for welding enterprises:

en15085 certification for rail vehicle and component welding factories

en1090 certification for steel and aluminum structure factories

en iso 3834 certification for welding quality systems

2. welding procedure qualification:

en iso 15614 series standards

asme section ix

aws d1.1

3. welder/welding operator certification:

en287-1, en iso 9606 series standards

indian boiler regulations (ibr)

asme section ix

aws d1.1

4. certified welding inspector (cwi) certification:

conducting training and certification services for welding inspectors (cwi) authorized by the american welding society.

5. welding training and consulting services:

training on international welding standards

consultation on welding-related issues

1. customer presents specific requirements

2. professional personnel coordinate

3. prepare a professional testing plan

4. clarification or answering queries regarding the technical plan

5. quotation

6. signing of the technical service contract

7. project execution

8. project closure summary

(1) determine if a welding unit can create welded joints that meet the standards and technical requirements set by relevant national or industry guidelines.

(2) confirm whether the welding procedure specifications (wps or pwps) developed by the welding unit are accurate.

(3) provide a dependable technical foundation for creating official welding procedure guides or welding procedure cards.

tel: 86-400 821 5138

fax: 86-21 3327 5843

email:noa@noagroup.com